|  |

| |||||||||||||||||||||||||||||||||||||||||

![[Note]](/file/20207/2014.07.ftp.comtrol.com.tar/ftp.comtrol.com/html/images/note.gif) |

|

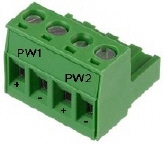

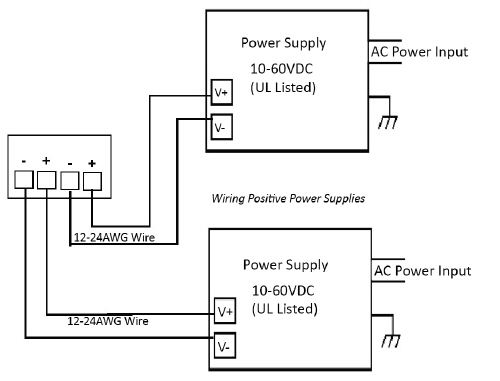

Insert the wires (12-24 AWG) from the power supply into the terminal block connector contacts.

Tighten the wire-clamp screws to prevent the DC wires from becoming loose.

The PW1/PW2 LED turns red during the boot cycle and turns green when the unit is ready. The recommended working voltage is 24VDC with an input range of 10VDC to 60VDC and a maximum power consumption of 15W.

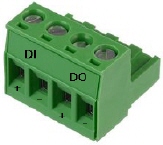

If desired, connect the digital input or relay output.

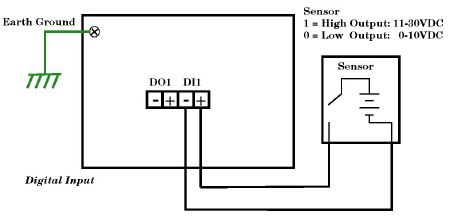

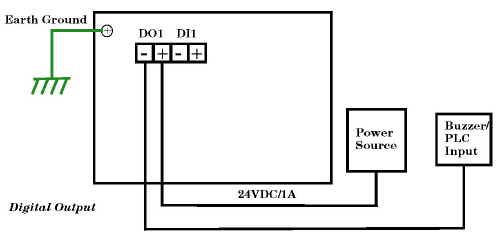

The ES8508 provides one digital input and one digital output (dry relay output) on the terminal block connector on the bottom of the switch. The fault conditions can be configured in the web interface and include:

The Digital Input pin can be pulled high or low so that the connected equipment can actively drive these pins. The web interface allows you to read and set the value to the connected device. The power input voltage of logic low is 0 to 10VDC and logic high is 11 to 30VDC. Do not apply a higher voltage than the specification; it may cause internal circuit damage or a cause an incorrect DI action.

Digital output relay contacts are energized (open) for normal operation and will close for fault conditions.

The digital output relay contacts support up to 1A at 30VDC. Do not apply voltage and current higher than the specifications.

To ensure the system is not damaged by noise or any electrical shock, we suggest that you to make an exact connection between the ES8508 and earth ground. On the bottom side of the ES8508, there is one earth ground screw. Loosen the earth ground screw with a screw driver; then tighten the screw after the earth ground wire is connected.

If you are going to mount the ES8508 on a grounded DIN rail, you do not need to also connect the ground wire.

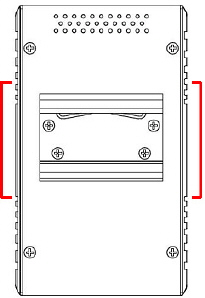

Mount the ES8508 to the DIN rail using the clip on the back of the unit or use the wall mounting plate.

Follow the steps below to install the ES8508 on a DIN rail:

If necessary, use the screws to attach DIN rail clip to the rear panel of the ES8508. (To remove DIN rail clip, reverse Step 1.)

Insert the upper end of DIN rail clip into the back of DIN rail track from its upper side.

Lightly push the bottom of DIN rail clip into the track.

Verify that the DIN rail clip is tightly attached on the track.

To remove the ES8508 from the track, reverse the steps above.

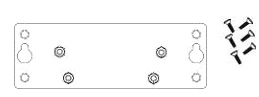

Follow the steps below to install the ES8508 with the wall mounting plate:

To remove the DIN rail clip from the ES8508, loosen the screws from the DIN rail clip.

Place the wall mounting plate on the rear panel of the ES8508.

Use the screws to attach the wall mounting plate to the ES8508.

Use the hook holes at the corners of the wall mounting plate to hang theES8508 onto the wall.

To remove the wall mounting plate, reverse the steps above.

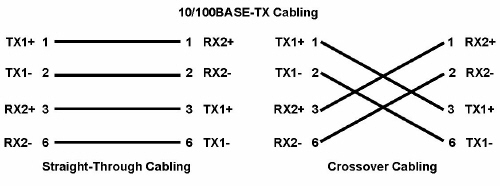

Connect appropriate network cables between the ES8508 Ethernet ports and the network.

The RJ45 ports support 10/100Mbps half/full-duplex and auto-detect the signal from connected devices to negotiate the link speed and duplex mode. Auto MDI/MDIX allows users to connect another switch, hub, or workstation without changing straight-through or crossover cable.

Always make sure that the cables between the switch and attached devices (for example, switch, hub, or workstation) do not exceed 100 meters (328 feet).

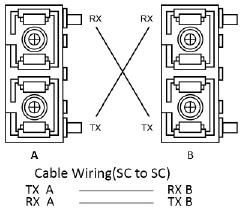

Optionally, connect the fiber port to another fiber Ethernet device using the following diagram. An improper connection will cause the fiber port to not work properly. The fiber port is a standard or square connector (SC). Make sure that the fiber mode of the cable matches the fiber mode of the ES8508F or ES8508F-XT (Single-Mode or Multi-Mode)

![[Note]](/file/20207/2014.07.ftp.comtrol.com.tar/ftp.comtrol.com/html/images/note.gif) |

|

You can refer to the RocketLinx ES8508 Series User Guide if you require cabling specifications.

Verify that the LEDs display that it is ready to configure the IP address.

The Link/Act LED is lit when the cable is correctly connected.

| LED | LED On | LED Blinking | LED Off |

|---|---|---|---|

| SYS | Green: system ready | Green: firmware loading | Power off |

| PWR1/2 | Green: system power ready | No applicable | System not ready |

| R.S. (Ring status) | Green: Ring is normal Amber: Abnormal ring | Green: Ring with wrong port Amber: The device's ring port failed | Switch working in slave mode |

| DO1 | Relay is active and contacts have been shorted | Not applicable | DO not activated |

| DI1 | High digital signal detected | Not applicable | DI not activated |

| LNK/ACT | Port is linked | Port active | Port link down or the port is not connected |

Configure the IP address using one of the following methods:

Web browser

Telnet

Command line interface (CLI) using the RS-232 console cable

The easiest way to configure a static IP address for your network in the ES8508 is to use a Windows host and PortVision DX (see Programming the IP Address). For information about using other configuration methods, refer to the RocketLinx ES8508 Series User Guide.

![[Note]](/file/20207/2014.07.ftp.comtrol.com.tar/ftp.comtrol.com/html/images/note.gif) |

|

The following procedure uses PortVision DX to program a static IP address. If you need to configure the ES8508 for DHCP you can use one of the other network configuration methods discussed in the RocketLinx ES8508 Series User Guide.

Install PortVision DX on a host system with a Windows operating system.

If you need assistance installing PortVision DX, see the RocketLinx ES8508 Series User Guide.

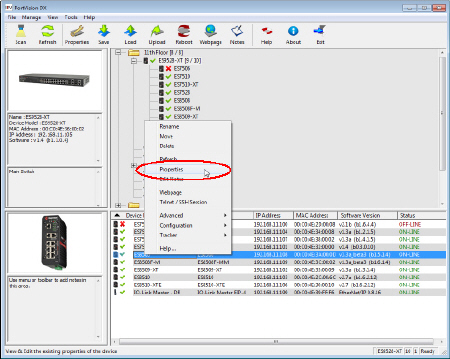

Start PortVision DX. PortVision DX can be started from Start --> All Programs --> Comtrol --> PortVision DX.

Select the Comtrol product families that you want to locate and click the Scan button.

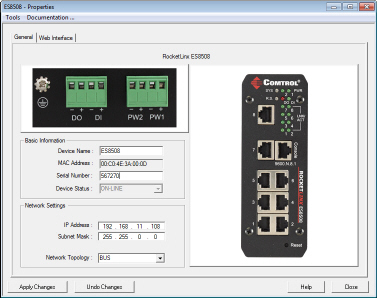

Configure the ES8508 IP address for your network.

Right-click the ES8508 in the Device List pane (lower) that you want to configure and click Properties.

Optionally, enter the ES8508 serial number, which displays a friendly device name in the Device List pane on the main page.

Optionally, select the appropriate Network Topology, which is an informational field.

You are now ready to configure the ES8508 features.

The ES8508 provides both in-band and out-band configuration methods:

Out-band management means that you configure the ES8508 using the RS-232 console cable and the Command Line Interface (CLI) to access the ES8508 without attaching an admin PC to the network. You can also use out-band management, if you lose the network connection to the ES8508.

In-band management means that you connect remotely using the ES8508 IP address through the network. You can remotely connect with the ES8508 Java applet web interface or a Telnet console and the CLI.

The following procedure uses a web browser to configure ES8508 features. Refer to the RocketLinx ES8508 Series User Guide for other configuration methods.

If necessary, install the latest version of the Java Runtime Environment, which is required to run the web management interface.

Enter admin for both the user name and the password when prompted.

Use the web interface to configure your device as needed for your network.

You can refer to the ES8508 documentation library for additional information.

| 06/11/14 | Home | Comtrol Support |  | |

| Copyright © 2014 Comtrol Corporation. |  | ||