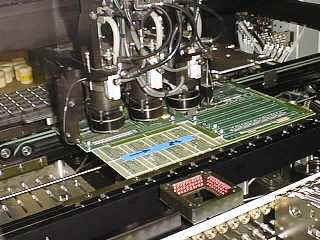

SMD LINE |

Assembly Advantages |

|

DCE has invested very heavily in automated, fully-CAD linked, manufacturing facilities over the last few years, and this, together with our long association with - and understanding of - the Amiga marketplace and technology made the phase5 Amiga products a very good fit for our own manufacturing capabilities.We are running 3 MPI Pick & Place Machines, which can process over 14000 components per hour and satisfy our increasing demands concerning finest pitches with a high precision 4 way optical vision positioning unit. Low to Mid Volume Surface Mount Production are our Specialty. |